Le Reblochon, est le résultat de l’alchimie de la nature et du savoir-faire d’exception de l’agriculture savoyarde.

Depuis 1958, le Reblochon ou Reblochon de Savoie, est reconnu par une Appellation d’Origine Contrôlée (AOC), désormais Appellation d’Origine Protégée (AOP) au niveau européen.

Afin de garantir au consommateur un produit authentique, préserver et transmettre les pratiques ancestrales de la fabrication du Reblochon, les opérateurs de la filière -producteurs de lait, producteurs fermiers, fromagers et affineurs- ont consigné dès 1958 les méthodes de production dans le Cahier des Charges définissant l’AOP.

Sont ainsi définis, protégés et contrôlés les critères suivants :

Le dispositif de reconnaissance, de suivi et de contrôle des A.O.P. est géré par l’INAO (Institut National de l’Origine et de la Qualité).

Le lait utilisé pour la production du Reblochon est transformé cru et entier. Durant toute la fabrication, le lait ne subit aucun traitement thermique supérieur à 37°C, il n’est ni cuit, ni pasteurisé.

La croûte du fromage est fine, de couleur jaune orangée et recouverte d’une fine mousse blanche.

Sa pâte est douce et onctueuse, de couleur blanche à ivoire, présentant quelques petites ouvertures. Son goût typique rappelle la crème avec un léger goût de noisette.

Le saviez-vous : Lorsque le lait sort de la vache il est à 35°C. Dans la fabrication du Reblochon fermier le lait est transformé en fromage directement après la traite avant même qu’il n’ait pu refroidir !

Plus d’informations et recommandations sur la consommation du lait cru :

Le Reblochon est une Appellation d’Origine Protégée (AOP).

La production de ce fromage se situe à la troisième place en volume des Appellations d’Origine. Le Reblochon bénéficie d’une Appellation d’Origine Protégée (A.O.P.) depuis 1958.

Pour garantir au consommateur un produit authentique, les opérateurs de la filière, producteurs de lait, producteurs fermiers, fromagers et affineurs, ont convenu au cours des précédentes décennies, de méthodes de production consignées dans leur Cahier des Charges définissant l’A.O.P.

Des contrôles sont effectués régulièrement en interne et par un organisme certificateur indépendant.

La forme du Reblochon doit être un cylindre plat de 13 à 14 cm de diamètre et de 3,5 cm d’épaisseur environ, pour un poids compris entre 450 et 550g.

Le Reblochon existe aussi en petit modèle. Son diamètre est d’environ 9 cm et son poids est compris entre 240 et 280g.

Au niveau du cahier des charges, rien ne différencie une AOP d’une AOC. En réalité, la différence entre l’AOP et l’AOC est d’ordre géographique et historique : l’AOC est un label français datant de 1935 alors que l’AOP est un label européen apparu en 1992.

L’AOC (Appellation d’Origine Contrôlée) est donc la plus ancienne certification. Elle a été créée afin de lutter contre les fraudes et valoriser certains savoir-faire existants dans un espace géographique clairement défini.

Vous souhaitez en savoir davantage ? N’hésitez-pas à regarder nos deux vidéos consacrées à ce sujet : “Pourquoi l’AOP ?” et “Qu’est-ce qu’une AOP ?”

Dans le même temps, plusieurs pays européens ont eux aussi développé leurs propres labels. Aussi dans un souci d’harmonisation et de simplification, l’Union Européenne a instauré en 1992 l’AOP (Appellation d’Origine Protégée). Ce label international est plus facilement lisible par les consommateurs et permet aux producteurs d’être mieux protégés.

L’AOP a progressivement remplacé l’AOC ; d’ailleurs, depuis 2012, seule la mention AOP doit figurer sur les produits. Il est à noter que seuls les produits qui sont reconnus comme AOC peuvent ensuite être enregistrés comme AOP. Il peut ainsi s’écouler plusieurs années avant qu’une AOC ne soit reconnue comme une AOP.

Pour résumer, pour le consommateur, et le produit en tant que tel, il n’existe aucune différence entre AOP et AOC réelle : toutes deux garantissent au consommateur un produit de qualité élaboré à partir d’un patrimoine traditionnel émanant d’une zone géographique précise.

En revanche, pour le producteur, depuis que l’AOP a été mise en place, la protection de son travail, de son savoir-faire est étendue à toute l’Union Européenne, et selon certains accords, cette protection est quasiment valable dans le monde entier !

Tous les Reblochons de Savoie répondent évidemment aux règles de l’Appellation d’Origine Protégée fixées dans le cahier des charges, mais, il existe deux sortes de Reblochon, identifiables à la couleur, verte ou rouge, de leur pastille de caséine.

La pastille de caséine garantit l’origine du Reblochon et constitue sa traçabilité. Elle comporte le numéro de l’atelier de fabrication et le lot de fabrication identifiable avec un suivi par date de fabrication.

Le saviez-vous ? Cette pastille de couleur est en caséine. La caséine est un composant naturel du lait : la pastille est entièrement comestible !

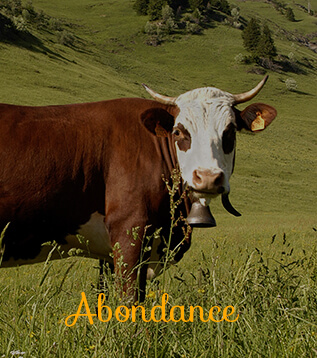

Only three cattle breeds are allowed to produce milk for Reblochon :

They are recognised for their ability to navigate mountain terrain, for their adaptation to the climate and the quality of their milk, which is ideal for cheese processing.

The feed given to cows producing milk for Reblochon is totally natural. The cows are mainly fed on grass (in the summer season) and hay from the area of the appellation (during the winter). The requirement is for them to graze in pastures for at least 150 days. Their feed is supplemented through the addition of grains (non-GMO).

The specifications strictly govern the feed given to the cows and no fermented food is allowed.